Strict authorized rules and rising buyer curiosity in security purposes that defend drivers and scale back accidents are driving the demand for driver help programs. As well as, reliability is turning into more and more essential to fulfill the ISO 26262 commonplace for useful security in automotive electronics. Passive elements which can be mechanically strong and may face up to sudden temperature fluctuations are required for automotive purposes. These embrace multi-layer ceramic chip capacitors (MLCCs), inductors for decoupling and energy provide circuits, and chip beads for sign and energy provide traces.

With a purpose to meet these security necessities, elements with plastic electrodes—that are also called “comfortable termination”—are used to scale back two widespread sources of error: bending and soldering cracks. On this weblog, we clarify how these errors may be prevented by “comfortable termination.”

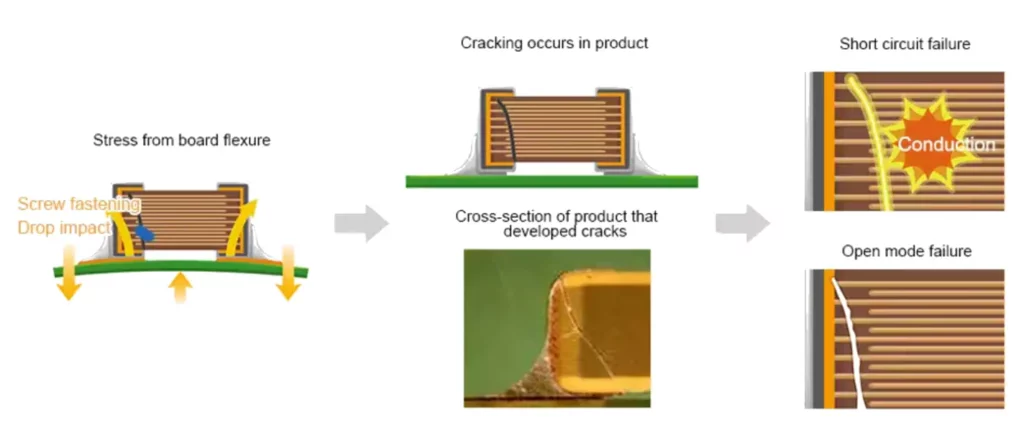

Major Causes of Flex Cracks

Flex cracks are attributable to extreme deflection of the circuit board. This may happen throughout the manufacturing course of, e.g., B. by soldering voltage on account of an excessive amount of solder, or by stress throughout desoldering or screwing. Flex cracks may also happen throughout ultimate meeting and operation when the circuit board is topic to fixed vibration.

MLCCs and ferrite elements are typically strong when below strain however weaker below stress. This distinction is partly because of the brittle nature of ceramics. When subjected to tensile stress, not like metals, they can not yield and relieve stress. Subsequently, a soldered element can simply crack if it bends an excessive amount of.

Avoidance of Flex Cracks

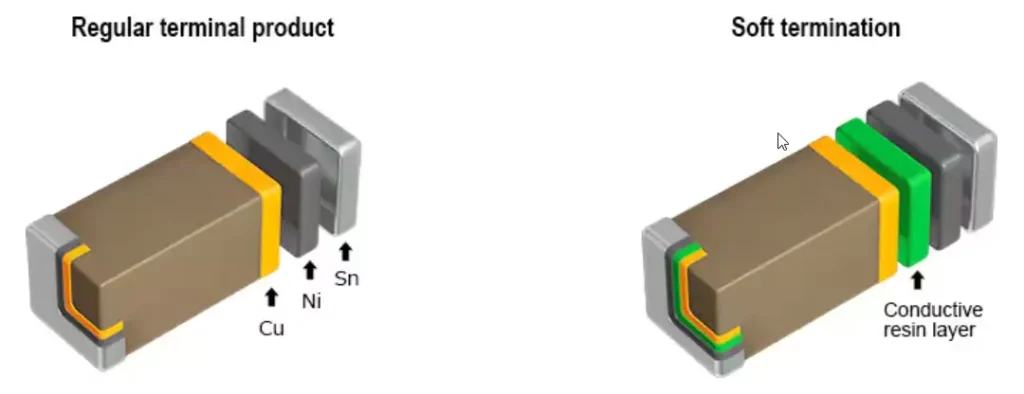

The terminal electrode of a standard MLCC has the decrease copper (Cu) layer electroplated with nickel (Ni) and tin (Sn). A conductive resin layer between the Cu and Ni layers creates a versatile connection (comfortable termination). This resin layer reduces the stresses attributable to enlargement or contraction of the solder joints on account of temperature modifications or bending stresses on the circuit board, inflicting cracks within the capacitor factor.

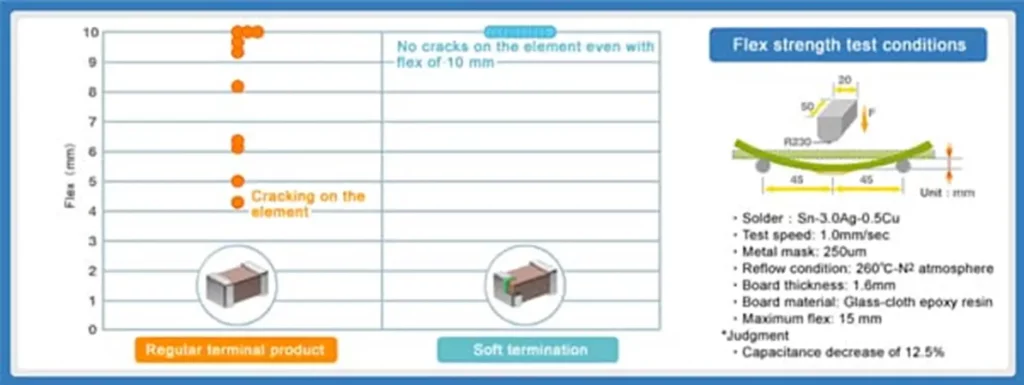

A comparability of the flexural power reveals that the usual product begins to crack at round 4mm of deflection. In distinction, comfortable termination merchandise don’t crack even when subjected to a bending stress of greater than 10mm. Though the nickel layer and the conductive resin layer peeled off, cracks within the ceramic physique had been prevented.

Taking this a step additional, security in battery-power provide traces may be considerably improved by changing a standard MLCC with a dual-safety MLCC. Twin-safety design MLCCs provide the best safety in opposition to cracks and brief circuits. First, the conductive resin is layered within the terminal electrodes to stop cracking. Then again, the internal electrodes have a particular construction that corresponds to a collection connection of two capacitors. This construction reduces the danger of brief circuits even when a crack happens on the capacitor factor. As a result of a single MLCC in collection meets AEC-Q200 security necessities, thus eliminating the necessity to daisy chain two commonplace MLCCs.

Much like standard inductors and chip beads, the silver electrode (Ag) is coated with Ni and Sn on the underside. A shatterproof connection is achieved by making use of a conductive resin layer between the Ag and Ni layers.

In comparative exams, multi-layer inductors and chip beads with resin electrodes have demonstrated virtually twice the flexural power (important deflection) of merchandise with standard electrodes. With standard merchandise, cracks seem on the ceramic factor at a bend of about 4mm. Smooth termination merchandise, then again, can face up to a 7mm bend.

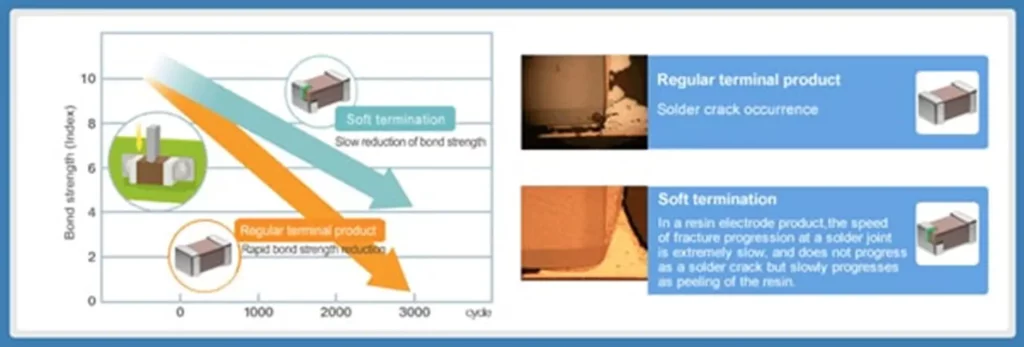

Major Causes of Thermal Cracks in Solder Joints

Cracks in solder joints are primarily attributable to thermal fatigue on account of thermal shock or thermal biking and/or the usage of lead-free solder, which is extra brittle than leaded solder. Subsequently, particular care ought to be taken when mounting passive elements close to robust warmth sources the place sudden temperature modifications (temperature shock) can happen.

If a solder joint is repeatedly thermally burdened, the totally different thermal enlargement coefficient (CTE) of the passive element and the circuit board can result in cracks within the solder. This may additionally happen if there may be inadequate temperature management throughout the soldering course of.

Different Enhancements in Smooth Termination Merchandise

Smooth termination merchandise have a conductive resin layer contained in the terminals to scale back mechanical stress. Nevertheless, this layer causes further resistance, which additionally impacts the ESR traits. To compensate for this drawback, TDK launched a brand new sort of soppy termination merchandise. The CNA collection MLCCs function a large terminal electrode on the PCB mounting aspect. The fabric elements of the connections are the identical as with standard comfortable termination merchandise. Nevertheless, the resin layer is utilized solely within the danger areas on the PCB meeting aspect. This gives efficient stress aid as all the connector space isn’t lined with resin.

Conclusion

Due to the improved robustness of soppy termination merchandise, the results of bending stresses and temperature fluctuations on the circuit board may be suppressed, rising the reliability of the connections. For extra data on TDK Smooth Termination MLCCs, see C Collection Smooth Termination MLCCs and CNA Collection MLCCs.

Writer: Mouser Electronics