To achieve Internet Zero, manufacturing extra merchandise within the UK that include recycled content material, and making certain that they’re reprocessed domestically, can be essential. One materials that exemplifies progress on this course is aluminium, says useful resource skilled EMR, which outlines essential initiatives and progress, beneath.

The aluminium recycling course of requires solely 5-10 p.c of the power wanted to supply the first steel, leading to vital carbon emissions financial savings.

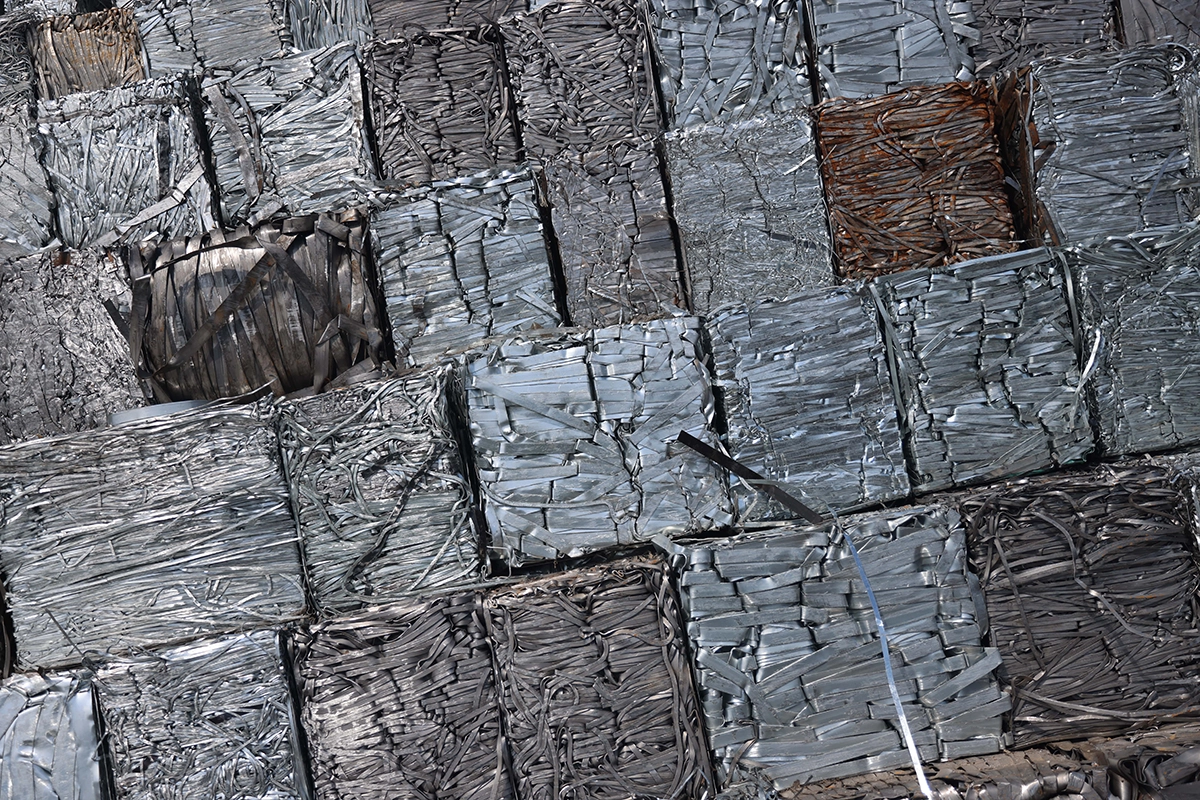

Presently, round two thirds (600,000 tonnes) of finish of life scrap aluminium within the UK is exported for recycling, the very best price in Europe.

To attain the top purpose of conserving 100% of our aluminium within the UK for use in domestically manufactured merchandise, stopping the necessity for the mining of latest materials and lowering pointless transportation, it would take a collaborative method.

EMR has been working intently with a string of companions throughout the aluminium manufacturing provide chain to find the boundaries to utilizing recycled content material within the UK, and to determine methods to convey them down.

As the most important recycler of end-of-life car (ELVs) within the UK, now we have entry to a whole bunch of 1000’s of tonnes of aluminium yearly. So, as demand from producers for recycled content material will increase, we’re completely positioned to work with the largest producers to make these plans a actuality.

We’re additionally in a position to apply the teachings discovered from different, comparable partnerships now we have collaborated in. For instance, by means of the 2020 RECOVAS Partnership, with half funding from the Authorities’s Superior Propulsion Centre (APC), we partnered with a number of the largest car producers on this planet, together with Bentley, Jaguar Land Rover and BMW , to develop a round EV battery recycling provide chain within the UK. And, because of this, now we have a EV battery recycling facility launching within the UK later this 12 months, together with our EV battery facility in Hamburg.

Final 12 months, we additionally initiated the Re-Rewind Partnership, which noticed EMR associate with specialists to recycle uncommon earth magnetic supplies. This challenge is part-funded by Innovate UK, and led to us establishing a wind turbine reprocessing facility in Glasgow.

Separation methods

One of many predominant boundaries to introducing extra recycled aluminium into the manufacturing course of is that present grade specs for essential structural elements are primarily based on the qualities of virgin materials.

Present recycled grades within the UK are a mixture of alloys, so include a mixture of different metals, thus altering the make-up and so specs of the fabric.

By working with our automotive business companions, together with main Automotive Tier 1 provider, Constellium, we intention to regulate the grade specs for essential structural elements and so use extra recycled content material, with out compromising efficiency. Constellium are main an thrilling R&D challenge referred to as CirConAl, with funding from the APC which is testing new scrap-tolerant alloy formulations for car functions.

Moreover, EMR is continually bettering its recycling separation processes to cut back contaminants and get well greater grades of fabric, making certain materials can re-enter the round financial system, match for function, and be utilized in domestically manufactured merchandise.

The environmental advantages of utilizing recycled aluminium are plain. By doing so, we will considerably scale back reliance on virgin supplies, preserve materials throughout the UK and dramatically decrease carbon emissions all through the manufacturing course of.

Nonetheless, EMR is dedicated to demonstrating the robust enterprise case as nicely. Our improved separation methods allow us to get well extra usable aluminium, leading to greater yields.

Moreover, substituting main aluminium with recycled aluminium can result in a dramatic discount within the embodied carbon footprint of the manufacturing course of.

By creating a better high quality product by means of superior separation, EMR justifies the retention of finish of life aluminium within the UK for additional processing, as a substitute of exporting it as lower-grade blended alloys.

The rising demand for top of the range, recycled aluminium supplies within the automotive business specifically, creates a compelling enterprise case for collaboration.

We envision a future the place recycled aluminium turns into the norm in UK manufacturing, and our dedication to working in collaboration to make this occur, not solely advantages the setting, but additionally unlocks monetary benefits.