Actuators are a significant part in a variety of programs utilized in water, vitality and different industries. However what precisely is an actuator? Newcomers to the subject are sometimes content material to consider this part as merely a swap, of types – the a part of a valve-based system that brings the valve to an open or closed place. However the worth of such components more and more goes past easy “open-close” performance and right into a realm the place all types of subtle management turns into potential, as Envirotec found in dialog with AUMA Actuators UK, the UK arm of AUMA Group, which employs over 2,800 folks in 30 areas wortldwide.

Valves have a significant position to play in programs the place fluid (or fuel) movement must be managed. In functions the place water flows by pipelines, for instance, it may be crucial for the movement to be stopped, began, slowed, or for its course to be modified. In some programs, valves will likely be known as upon to control stress in other places.

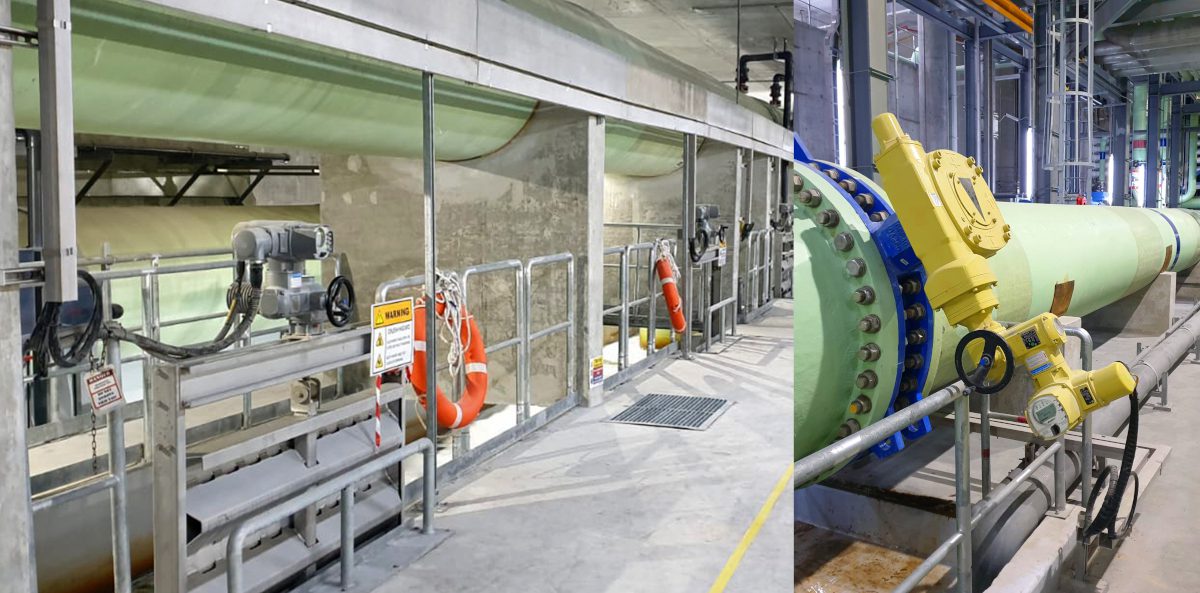

The water trade is a primary vacation spot for these parts, though they seem in an enormous vary of course of know-how and different programs, together with energy technology, whether or not or not it’s from oil, fuel, biomass, energy-from-waste, or nuclear. Actuators play a significant position within the management course of.

At this time’s electrical actuators will be remotely managed, and obtain instructions to open or shut from industrial management programs like SCADA or DCS. Equally, when the actuator has reached a selected cease or intermediate place, it should sign this standing to the management system.

This sort of performance is the baseline – and can suffice for a lot of customers – however way more subtle management is feasible, and AUMA’s providing more and more incorporates varied sorts of ‘sensible’ performance. That is the place an evolution of the know-how round valves and actuators is most seen, suggests AUMA’s UK MD Paul Hopkins, who supplied a way of the probabilities coming into view with a subsystem that, he stated, “is definitely an thrilling piece of engineering”.

What does it do?

AUMA’s electrical actuators function a mixture of an electrical motor and gearbox, specifically developed for valve automation. Actuators present the torque wanted to function the transferring components of the valve, whether or not or not it’s gate, butterfly, globe or another kind of valve. As AUMA’s web site states, the agency’s actuators deal with the complete vary of potentialities, from a 2-inch ball valve to diverter dampers many metres excessive (see “Valves: the fundamentals”, on the finish of the article, for extra on valves).

The torque is transmitted from the actuator to the valve stem or shaft by way of a standardised mechanical interface. So the kind of valve determines the selection of actuator, with actuators accessible as “part-turn” or “multi-turn” gadgets.

The part-turn actuators solely require a small quantity of rotational motion (lower than 90 levels) to open or shut the valve, and are usually used for valves working in a fast on/off vogue. The multi-turn actuators apply a number of rotations to the valve stem to completely open or shut the valve, and are used the place the valve positioning must be exactly managed, as with gate, globe or rising stem valves.

Typically it’s necessary to fastidiously management the torque utilized when opening or closing a valve, to keep away from damaging the valve or the method it’s controlling, defined Hopkins. Actuators additionally present the interface between the valve and management programs (and intelligence embedded throughout the wider system), and this facet is turning into more and more necessary with developments comparable to IIoT and Business 4.0.

AUMA offers the baseline degree of management performance in its AM vary of actuator controls, and these components are stated to be the right alternative the place you merely need to have the ability to report the actuator’s finish place and fault alerts (that are additionally visibly displayed by lights on the unit). Further management features are potential with the agency’s AC vary of controls, stated to be an appropriate alternative the place you want knowledge logging, or self-adapting management features, or the place the valve-actuator is built-in inside a system geared up for issues like asset administration and distant upkeep. The half incorporates microprocessor management, offering way more complete performance says Hopkins, in addition to the choice of connecting it to course of automation by way of Fieldbus (parallel interface can be accessible, as with the AM controls).

The AC unit additionally offers features comparable to torque bypass, to un-seat valves which can be tightly seated, and features to assist with avoiding water hammer in pipelines. Hopkins situates components like these throughout the Business 4.0 paradigm, and the three layers of the management system: the sensors (“to inform you what’s occurring”), the method controller (“to inform the system what it ought to be doing”) and the bodily layer or output gadgets. Actuators match into this final degree of the system.

Varied diagnostic features are offered by the AC, together with a time-stamped occasion report, and logging of torque traits, in addition to the variety of begins and motor working instances. Steady monitoring of temperature and vibration is a function that may assist finish customers to maintain their vegetation working reliably, suggests Hopkins, providing a match with trendy water trade aspirations for “no outages” and so forth.

Tackling water hammer

A lot mentioned within the water trade at current is the topic of leakage, and greater than 1 trillion litres of potable water was misplaced by way of leaky pipes in England and Wales in 2021/22, as a latest AUMA video explains. The identical presentation explains how variable pace actuators will be programmed to assist calm the water community, avoiding the harm brought on to pipes by sudden transient surges. This “water hammer” impact arises when valves shut instantly or at excessive pace, producing a high-pressure wave that propagates by the community, placing stress on valves, seals and mechanical parts, whereas additionally generally damaging pipework.

One answer is to range the pace at which these valves open or shut, in an clever means, making an allowance for the general effect on pressure-change dynamics all through the community. AUMA’s variable pace actuators will be programmed, and the valve journey (in each opening and shutting instructions) will be divided into ten di erent sections, with it being potential to specify different speeds for every.

This sort of answer can be utilized inside a water community geared up for monitoring, analysing and performing upon stress transients, lowering the probability of asset harm.

Placing components collectively

In the actual world, valve-actuator programs appear to fall throughout a spectrum of sophistication and complexity, and AUMA product vary is constructed utilizing a modular design philosophy, which is usefully geared in direction of addressing the distinctive necessities of particular customers.

On one degree, says the agency, the modular product design helps issues like simple retrofit and restore, and programs will be simply upgraded from AM to AC controls, for instance (and backward compatibility is preserved too). The strategy additionally makes it simpler to offer the optimum mixtures of parts throughout the actuator (comparable to gearboxes and linkages), tailor-made to the state of affairs, and the most effective methods of coupling them. Potentialities embody nearer

coupling of valve and actuator (reasonably than solely utilizing common joints), and having components just like the gearbox and motor individually situated from the controls – for instance, at peak, or down a pit, and even underwater. One instance of the place this got here in useful was with an underwater hydro turbine management software on the Sauerbrunn hydropower plant close to Graz, Austria, in Autumn 2022, leading to an answer that offered higher management and suggestions at a a lot decrease price.

The system required an actuator capable of function repeatedly underwater, to offer correct positioning of the turbine, to optimally management the water provide it obtained. The one choice beforehand had been a hydraulic actuator, however AUMA was capable of counsel an electrical actuator suited to underwater use (the AUMA SARV-UW), together with actuator controls mounted above the shaft and individually from the actuator (and above water).

Completely different environments

A modular answer can choose from components specified to deal with explicit environments. Whereas broadly related applied sciences are used throughout sectors like oil and fuel, EfW, and nuclear energy – by way of the valves and actuators used with boilers, for instance – some sectors current particular calls for. Oil, pure fuel or EfW vegetation would require components to be explosion-proof, for instance (AM and AC merchandise can be found on this kind).

Certification is of the utmost significance within the nuclear sector, stated Hopkins, and components are distinguished by issues like the extent of certification, the sourcing of supplies, and the equipment or housing used with the product.

AUMA has an curiosity in each the rising area of small modular reactors (SMRs) and in addition bigger initiatives comparable to Hinkley Level C. Corrosion safety is necessary in sectors like water, the place gear would possibly want to take a seat exterior, within the presence of saline, coastal air. AUMA has developed its personal answer right here, which is equipped as commonplace, for instance, on its PROFOX actuators, used just lately along with butterfly valves at Penybont Water Remedy Works on the midWales coast. The corrosion safety meets the best C5-M/ C5-I necessities of EN ISO 12944-6.

Easing the load

The modular design philosophy appears to be a key underpinning quite a few issues that may make life simpler for the top consumer. For instance, in conditions the place it makes way more sense to take a largely prefabricated answer to a web site, reasonably than assembling all of it in situ. Doing o web site work additionally helps maintain issues secure, says Hopkins, so electrical work will be carried out individually, and at a different time, from the remainder of an set up, for instance.

Quite a lot of flexibility is accessible to identify alternatives to enhance or improve an end-user’s gear, he suggests. One of many greatest factors of failure within the water trade, in his personal evaluation, arises from the shaft in a penstock valve not being correctly greased.

He stated AUMA’s engineers centered on this spot with one water utility buyer, offering an autogreaser that not solely greases the bearings but additionally feeds into the drive base and greases the shaft. A change like this, says Hopkins, “is easy, however doubtlessly saves tons of of hundreds of kilos on the penstock” and drastically decreases the variety of instances it should be serviced.

This sort of “consultative promote” seems key to the best way the corporate works, and it depends on engineering experience. Dad or mum firm – AUMA – has been growing and constructing electrical actuators and valve gearboxes for 60 years. The massive community of places of work all over the world means engineers within the UK can draw on the experience of others, who might have expertise of fixing a selected kind of downside.

The previous few years have additionally seen quite a lot of turmoil with supplies, manufacturing and provide chain points, says Hopkins, and navigating this territory has been helped by AUMA’s being “very vertically built-in”, with websites just like the Clevedon o ice of AUMA Actuators Restricted doing its personal machining, meeting, take a look at and restore.

The components themselves are manufactured in Germany, with factories working in a “kanban” system, pulling demand by reasonably than holding inventory. So far as capability goes, Hopkins says the agency builds greater than 500 electrical actuators to order day by day.

[ SIDE PANEL ]

Valves – the fundamentals

Valves are available all styles and sizes, with different approaches accessible to go well with particular wants, by way of issues like price, pace, reliability and so forth. Some functions require the valve to be merely opened or closed, whereas in others you would possibly want to maintain it in varied intermediate positions, to control the fluid movement.

One widespread apply is to divide the world of management valves into components based mostly on linear movement (gate, globe, and diaphragm valves), vs these based mostly on rotary movement (ball, plug and butterfly valves, for instance). Gate valves are the most typical in use at present, given their relative simplicity and low price. These can be utilized to begin and cease fluid movement, however to not throttle it. Gate valves aren’t appropriate to throttling movement, and will be topic to vibration when left in a partially-open place. They’re additionally extra prone to su er seat and disc put on, and leaking, in comparison with globe valves, for instance.

[ END OF SIDE PANEL ]