Their method might rework a scientific area reliant on cost-prohibitive expertise.

Researchers on the Georgia Institute of Know-how have developed a light-based technique of printing nano-sized steel buildings that’s considerably sooner and cheaper than any expertise at present accessible. It’s a scalable answer that might rework a scientific area lengthy reliant on applied sciences which can be prohibitively costly and gradual. The breakthrough has the potential to carry new applied sciences out of labs and into the world.

Benefits of the New Approach

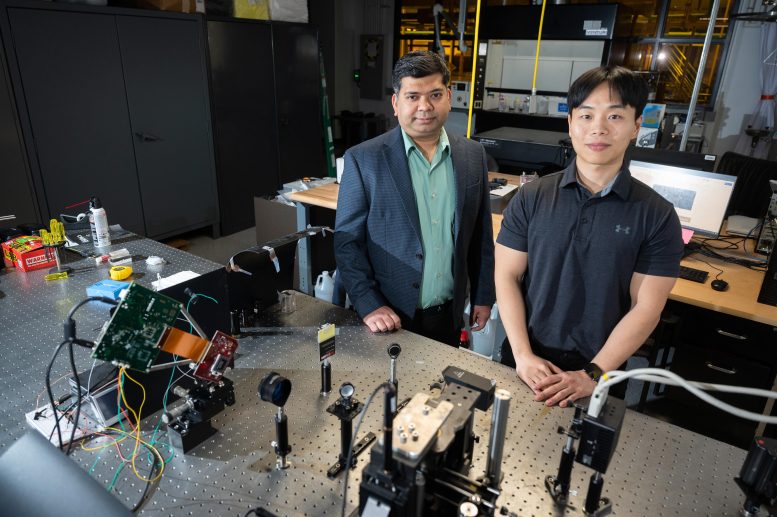

Technological advances in lots of fields depend on the flexibility to print metallic buildings which can be nano-sized — a scale a whole bunch of instances smaller than the width of a human hair. Sourabh Saha, assistant professor within the George W. Woodruff Faculty of Mechanical Engineering, and Jungho Choi, a Ph.D. pupil in Saha’s lab, developed a method for printing steel nanostructures that’s 480 instances sooner and 35 instances cheaper than the present standard technique.

Their analysis was revealed within the journal Superior Supplies.

Assistant Professor Sourabh Saha and Jungho Choi (Ph.D. pupil) in entrance of their superluminescent gentle projection system at Georgia Tech. Credit score: Georgia Institute of Know-how

Overcoming Conventional Limitations

Printing steel on the nanoscale — a method often called nanopatterning — permits for the creation of distinctive buildings with fascinating capabilities. It’s essential for the event of many applied sciences, together with digital gadgets, photo voltaic vitality conversion, sensors, and different methods.

It’s typically believed that high-intensity gentle sources are required for nanoscale printing. However one of these software, often called a femtosecond laser, can price as much as half 1,000,000 {dollars} and is simply too costly for many analysis labs and small companies.

“As a scientific neighborhood, we don’t have the flexibility to make sufficient of those nanomaterials rapidly and affordably, and that’s the reason promising applied sciences typically keep restricted to the lab and don’t get translated into real-world purposes,” Saha mentioned.

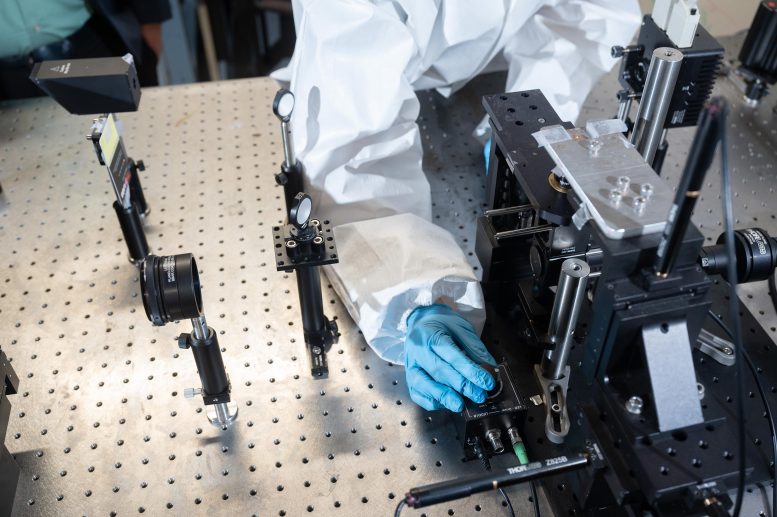

Ph.D. pupil Jungho Choi controlling LED brightness ranges on the SLP system. Credit score: Georgia Institute of Know-how

“The query we needed to reply is, ‘Do we actually want a high-intensity femtosecond laser to print on the nanoscale?’ Our speculation was that we don’t want that gentle supply to get the kind of printing we wish.”

They looked for a low-cost, low-intensity gentle that may very well be centered in a method just like femtosecond lasers, and selected superluminescent gentle emitting diodes (SLEDs) for his or her business availability. SLEDs emit gentle that could be a billion instances much less intense than that of femtosecond lasers.

A video of nanoprinting with superluminescent gentle projection (SLP). Credit score: Georgia Institute of Know-how

Progressive Printing Know-how

Saha and Choi got down to create an unique projection-style printing expertise, designing a system that converts digital pictures into optical pictures and shows them on a glass floor. The system operates like digital projectors however produces pictures which can be extra sharply centered. They leveraged the distinctive properties of the superluminescent gentle to generate sharply centered pictures with minimal defects.

They then developed a transparent ink answer made up of steel salt and added different chemical substances to verify the liquid might soak up gentle. When gentle from their projection system hit the answer, it induced a chemical response that transformed the salt answer into steel. The steel nanoparticles caught to the floor of the glass, and the agglomeration of the steel particles creates the nanostructures. As a result of it’s a projection sort of printing, it will probably print a complete construction in a single go, quite than level by level — making it a lot sooner.

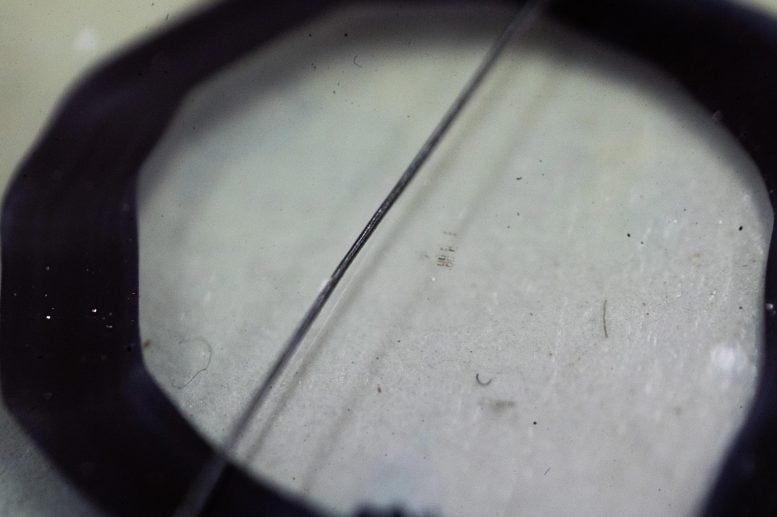

Measurement comparability between human hair (~100 micrometer thickness) versus printed silver pad on a glass coverslip. Credit score: Georgia Institute of Know-how

After testing the method, they discovered that projection-style nanoscale printing is feasible even with low-intensity gentle, however provided that the pictures are sharply centered. Saha and Choi consider that researchers can readily replicate their work utilizing commercially accessible {hardware}. In contrast to an expensive femtosecond laser, the kind of SLED that Saha and Choi used of their printer prices about $3,000.

Functions

“At current, solely prime universities have entry to those costly applied sciences, and even then, they’re situated in shared amenities and are usually not all the time accessible,” Choi mentioned. “We need to democratize the potential of nanoscale 3D printing, and we hope our analysis opens the door for larger entry to one of these course of at a low price.”

The researchers say their method might be notably helpful for folks working within the fields of electronics, optics, and plasmonics, which all require quite a lot of advanced metallic nanostructures.

Scanning electron microscope picture of printed silver GT sample Credit score: Georgia Institute of Know-how

“I believe the metrics of price and velocity have been tremendously undervalued within the scientific neighborhood that works on fabrication and manufacturing of tiny buildings,” Saha mentioned.

“In the actual world, these metrics are necessary in the case of translating discoveries from the lab to trade. Solely when we now have manufacturing methods that take these metrics under consideration will we be capable of absolutely leverage nanotechnology for societal profit.”

Reference: “Scalable Printing of Steel Nanostructures by Superluminescent Gentle Projection” by Jungho Choi and Sourabh Okay. Saha, 22 October 2023,Superior Supplies.

DOI: 10.1002/adma.202308112

Funding contains grants from the G.W.W. Faculty of Mechanical Engineering and the EVPR’s workplace on the Georgia Institute of Know-how. Imaging was carried out on the Georgia Tech Institute for Electronics and Nanotechnology, a member of the Nationwide Nanotechnology Coordinated Infrastructure (NNCI), which is supported by the Nationwide Science Basis (ECCS-2025462).